Exchange of experience in density measurement technology

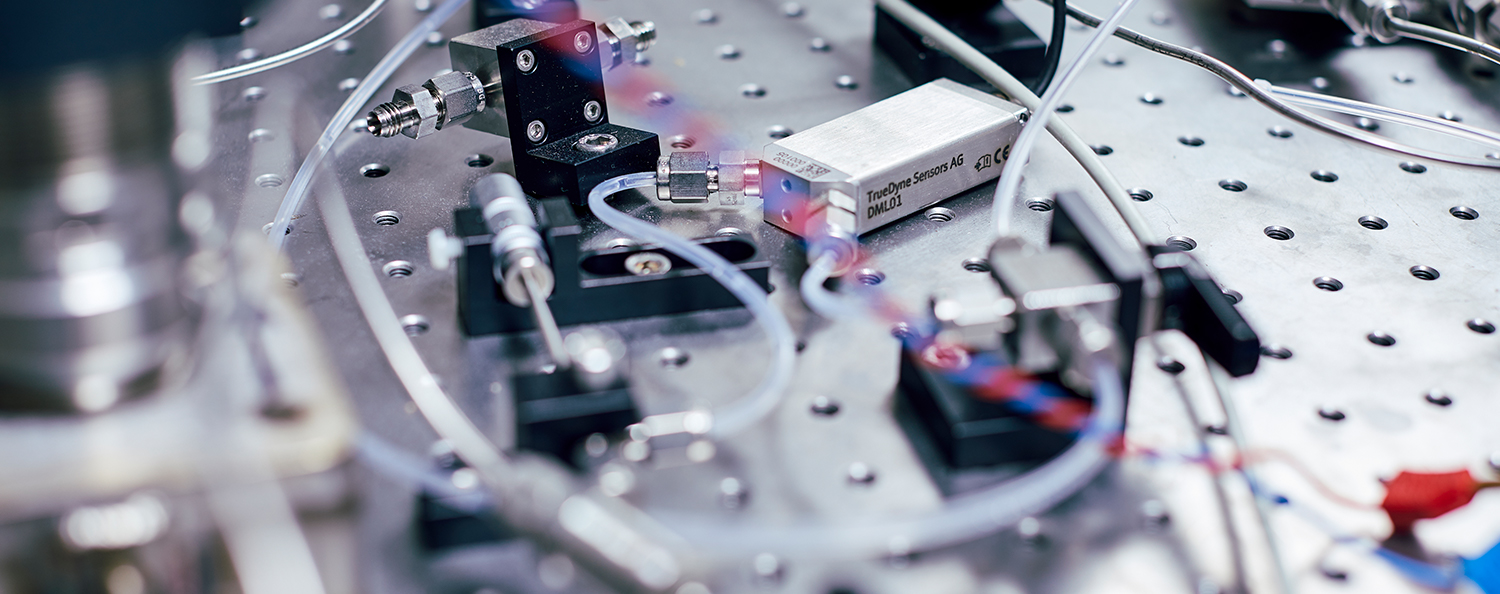

The verification of the density sensor DLO-M1 by the manufacturer-independent calibration laboratory Testo Industrial Services was successfully carried out within the cooperation project with TrueDyne Sensors AG.

For reliable measurement results of density sensors the two Flow rate and sealing specialists Testo Industrial Services GmbH and TrueDyne Sensors AG. Over the last few years, TrueDyne Sensors AG has been able to acquire a great deal of know-how in the field of microsensor technology and oscillating systems. A flexural vibration measuring system in MEMS technology with a measuring channel in sub-millimeter size - that is the density module of TrueDyne Sensors AG. Measurement systems such as these allow numerous companies new opportunities to expand and improve their products and production processes within the process. The high accuracy, the extremely compact design and the real time measurement play a central role in these density modules.

Testo Industrial Services GmbH supports the manufacturer of density sensors in ensuring these quality criteria. Because detailed measurements in an independent and accredited calibration laboratory ensure safety for the customer.

Your advantage: Our competence

- Provision of laboratory space and calibration test benches

- Many years of know-how in the field of calibration technology

- Definition of test procedures and measurement methods

- Derivation of argumentation approaches on the basis of the results

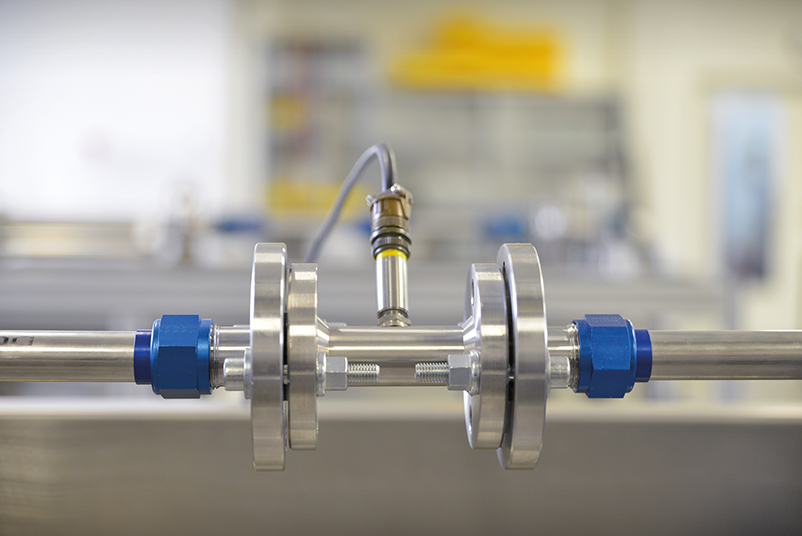

Equipment used for the measurements

- Calibration standard liquid - Testo KKF80 MU ± 0.08 % f.s.

- Temperature sensor 1/10 DIN

- Pressure sensor ± 0.04 % f.s.

- Density sensor DLO-M1 - TrueDyne Sensors AG

- VDI Heat Atlas 10th edition 2006, Dba14 Table 12.

- Kinematic viscosity water

- Density table according to NIST

Find out more about this success story and take a look at the Cooperation flyer.

More about our services

Our measured variables

we calibrate almost all measurands, with over 300 accredited calibration procedures.

Accreditation & Certification

Accreditation as calibration and testing laboratory

Service portfolio

Your partner for calibration, test equipment management, qualification and validation